COMPANY WELDING spol. s r.o.

ABOUT US

Welding, s.ro., Topoľčany is an engineering company building on the more than 50-year history of its predecessors. Welding is one of the small-middle size private engineering companies in Slovakia. Continuing the activities of its predecessors in recent decades – STS, š.p. Topoľčany (1951-1991) and HMC, s.r.o., Topoľčany (1991-2001) – the company specializes in the production of mechanical and structural steel structures. At Welding, special attention is paid to the production of dynamically stressed structures of technological equipment, such as e.g. precision technological pallets in the automotive industry, stators and base frames of large diameter electric motors and generators, dynamically stressed tracks and columns for amusement parks rides, pressure and non-pressure parts of boilers and other energy equipment, dynamically stressed structures of vibrating conveyors, road expansion joints, handling and storage equipment and others.

PRODUCTION PROGRAM

Production program of Welding s.r.o. has been profiled during its development. It is divided based on its structure on different branches, specifically on production of:

- Stator frames, base frames, rotor parts and other equipment for heavy motors and generators of large dimensions

- Amusement rides products such as tracks and columns of roller coaster, different parts for giant wheels and thrill rides for amusement parks

- Pressure and non-pressure parts of energetical equipment

- Various steel constructions of different types, for example: Heavy industrial conveyors, Bridge expansion joints, Base frames of machines, Warehouse and handling devices

- Steel constructions of industrial halls and bridges

- Steel constructions of automated people mover (APM) monorails

- Precise technological pallets for automotive

ENGINEERING TECHNOLOGIES

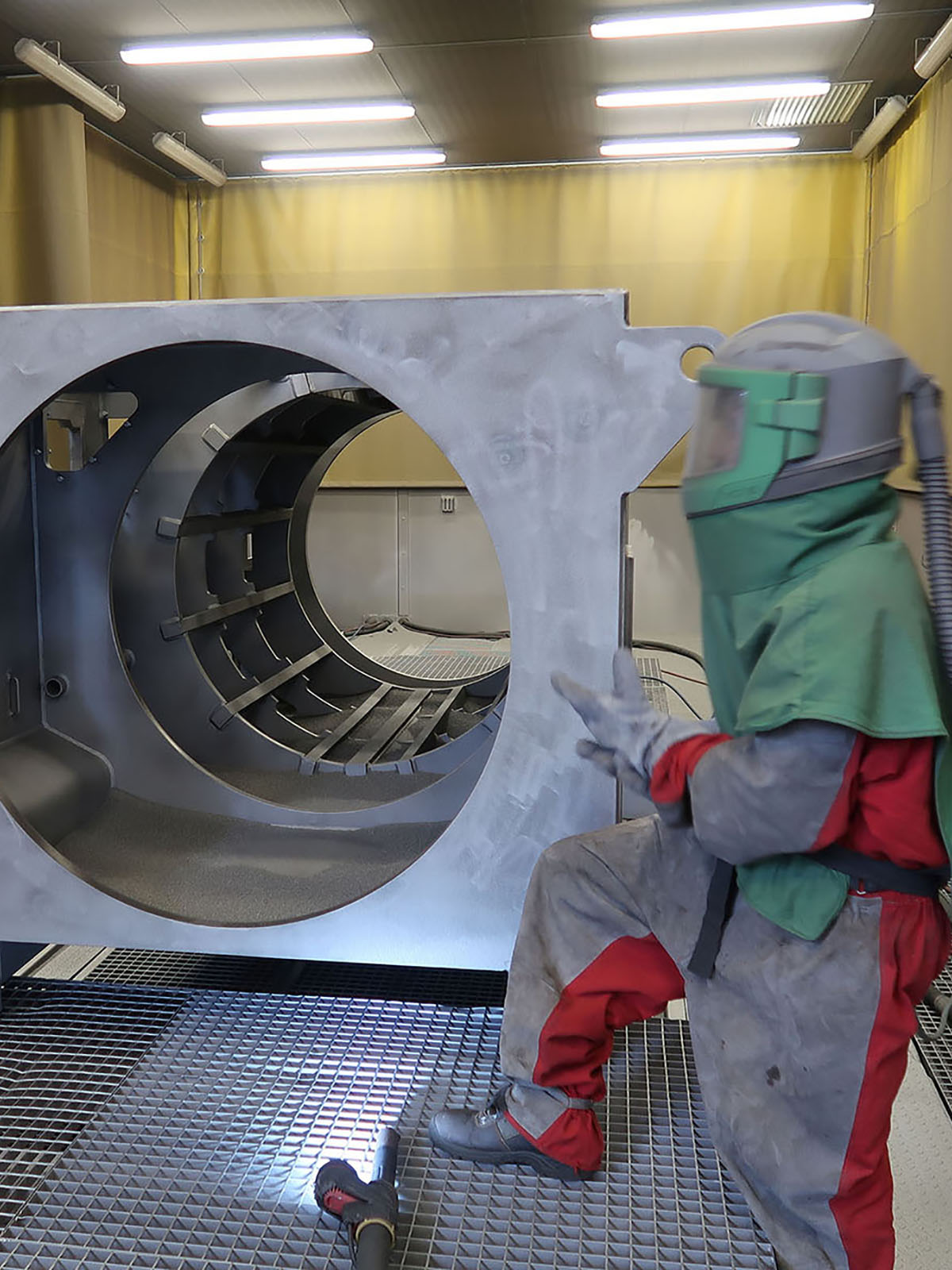

CORROSION PROTECTION

Corrosion protection of steel constructions provides not only long-term life cycle of the product but also pleasant visual look. At Welding s. r. o. we’ve put into operation most modern corrosion protection system for full range of our products – from stator housings of heavy motors and generators, base plates of heavy turbines, rotors units, bearings shields and stator core rings to amusement rides such as roller coaster tracks and columns.

Guarantee for proper corrosion protection is perfect clean and rough surface, free of corrosion, dirt and grease. After, it is subsequent use of the method of high-pressure application of wet paints – spray painting. Corrosion protection system center is localized in separate production hall of area 2040 m2, with lifting ability of 25,0/10,0 tons.